What is the difference between OEM and ODM? Which is better for developing original products? An easy-to-understand explanation of the differences and benefits!

What are OEM and ODM?

OEM: Specialized manufacturing outsourcing

OEM stands for "Original Equipment Manufacturing" and is a method of outsourcing the manufacturing of products sold under one's own brand to other companies. Planning and design are done in-house, and only manufacturing is outsourced.

ODM: Outsourcing everything from planning to manufacturing

ODM stands for "Original Design Manufacturing" and is a method of outsourcing everything from planning to manufacturing. The customer is only responsible for the brand name and sales.

*In Japan, the boundary between OEM and ODM is unclear, so they are often collectively referred to as OEM.

Difference between OEM and ODM

Strictly speaking, there are differences between OEM and ODM as described above, but in practice, any outsourcing that involves manufacturing is generally referred to as OEM. The reason for this is that in most cases, not only manufacturing but also the know-how of the client is utilized, making the boundary between OEM and ODM unclear.

Benefits of OEM/ODM

- Using your own ideas and data from existing businesses, you can develop multifaceted products that reflect market needs and track records.

- Planning, development, and design can be done together with the person in charge, so new entrants can enter the market even without know-how.

In order to successfully develop original products, it is important to understand OEM and ODM and make thorough preparations.

In order to successfully develop an original product, it is important to keep the following two points in mind.

Prepare well in advance

- Clarification of development objectives: Clarify the specific purpose of developing an original product.

- Clarifying your target audience: Identify your target audience - who you are selling your products to.

- Market Research: We research the market size and competing products to determine the product direction.

- Budgetary Securing: We calculate development costs, manufacturing costs, sales costs, etc. and secure the necessary budget.

- schedule: We create development schedules, manufacturing schedules, sales schedules, etc.

Find a trusted partner

- Development track record: Check what kind of product development they have done in the past.

- Technical ability: Make sure you have the necessary technical skills.

- communication: Make sure you can communicate effectively.

Original product development requires a lot of time and effort, and ongoing support is required even after the product is completed. Therefore, it is important to find a reliable partner with extensive development experience.

GRAIN Corporation's strengths in OEM and ODM

One-stop service

In the GRAIN,We handle everything related to commercialization (planning, development, raw material procurement, manufacturing, packaging creation, etc.). With our many domestic partner factories and raw material procurement capabilities, we can realize the products of our customers' dreams.

We can offer a wide range of solutions to meet customer needs, including GMP-certified plants, small-lot plants, and special dosage forms.

We start with a customer's request for a product, and provide total support for the shortest route to commercialization. As a business partner, we help turn our customers' ideas into reality.

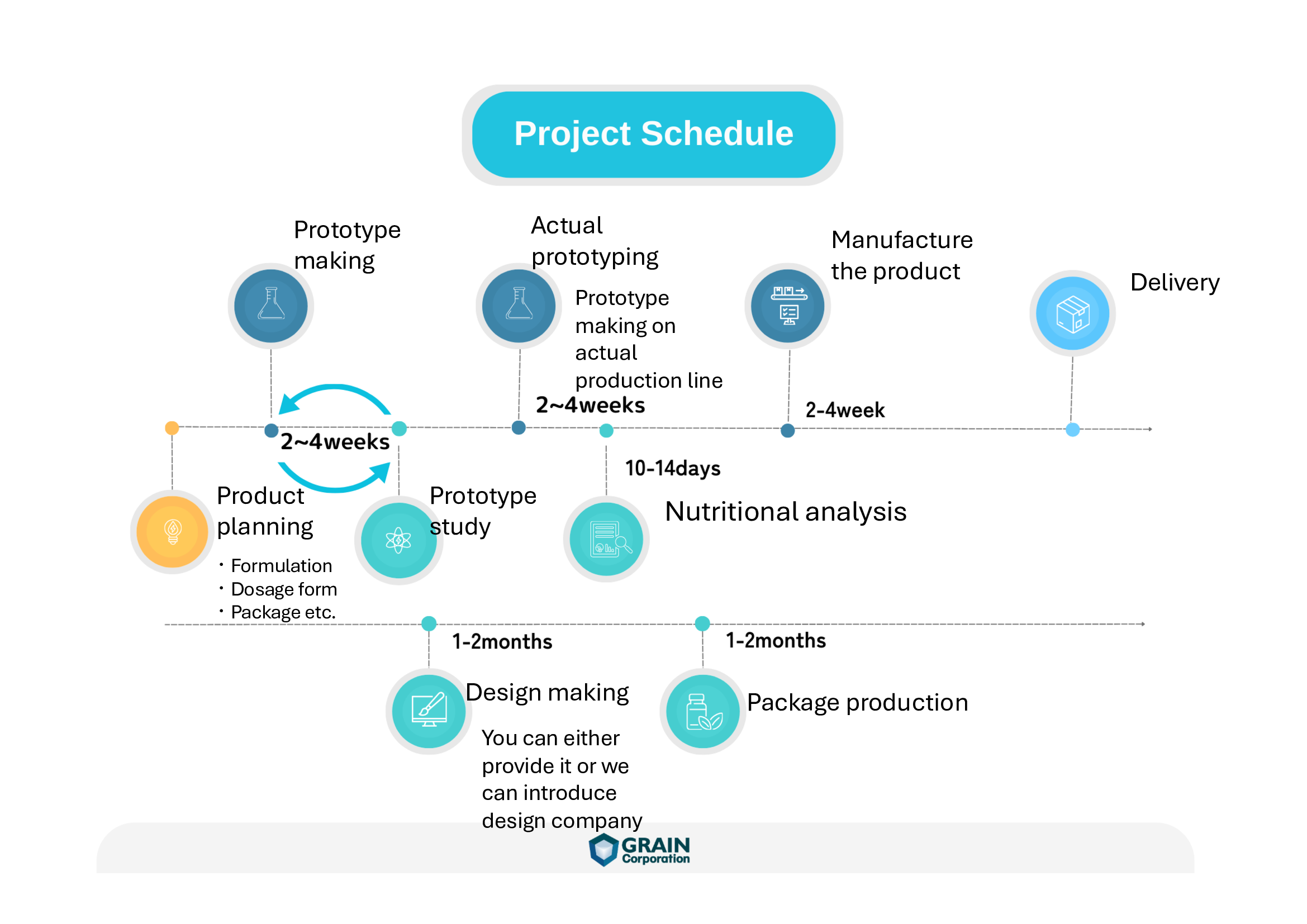

Schedule for commercialization (example of supplement manufacturing)

- 1. Product Planning

"I want to create a product that solves this problem," "I want a new product that fits into our company's market," "I want a product designed with this kind of concept in mind." Product planning starts with each customer's thoughts. Based on the customer's thoughts, we work together to create the shape of the product by examining it from various angles, such as the product's functions, costs, production lots, and market trends. - 2. Prototype creation

Once the product details have been decided, the next step is to create a prototype. By creating a real product, things that were not clear during the design stage become clear. - 3. Design

Once the product details have been finalized to a certain extent, we will begin creating the package design. You can provide us with the design, or we can provide you with the design. - 4. Prototype review

We will continue to consider the completed prototype and if any improvements are required, we will create other prototype and polish it up for commercialization. - 5. Actual prototype

After the specifications have been finalized, we finally begin the actual prototyping. Actual prototyping involves creating a prototype sample using the same machine that will be used to manufacture the product. The purpose of the actual prototyping is to make fine adjustments to the formulation required for the machine to process the product into tablets and fill it into capsules. After the actual prototyping, the final product specifications are finalized. - 6. Nutritional Analysis

The completed prototype sample is identical to the actual product, so we use it to conduct nutritional analysis. The results of the nutritional analysis must be listed on the package, as required by law. - 7.Product manufacturing

Once the delivery date for the package is confirmed, we secure the optimal production line for manufacturing the product. - 8. Delivery

Once the product is completed, it will be delivered to your desired location.

In this way, GRAIN plans the overall production schedule, adjusts each item required for commercialization, and commercializes the ideal product in the shortest time possible. For subsequent orders from the second time onwards, we will also adjust the production schedule, so our clients can rest assured and focus on sales promotion and marketing.

(If you are an overseas company and need to export from Japan to your local area, we can handle the export procedures and transportation arrangements. Please consult us in advance if you are planning to export your product.)